The Best Waterproof And Impact Resistance Solution for Electronic Components: Low Pressure Molding

Share

Advantages of Low Pressure Molding

"Low-pressure molding (LPM)" uses environmentally friendly rubber materials to form products, which is becoming a trend in the West. More and more customers choose or switch to "low pressure molding" because it has many advantages:

- IP 67 grade waterproof & harsh enviroment resistance.

- More productive due to reduced production steps and shorter cycle time per part to mold.

- Fulfill the need for waterproofing and impact resistance for electronic components.

- Potting takes a longer cycle time, 24 hours on average, while the LPM process takes around 45 - 60 seconds to complete molding. Additionally, it takes 8 steps to complete the process, and more spaces for curing when LPM completes the whole process in 3 steps.

Low Pressure Molding Process

LPM simplified the production process to only 3 steps to solve your pain points in molding!

Step 1: Insert parts

Step 2: Inject & Mold

- The injection pressure is low and helps to protect fragile electronic components. The eco-friendly materials provide better watertight encapsulation.

- Cycle time per part to mold only takes 45-60 seconds.

- Custom structure/shape for the products, as the materials can be skylined around electronic components.

Step 3: Test

- IP67 dustproof/waterproof. Products can be adapted to a harsh environment.

Consult COMOSS experts now !

Applications of Low Pressure Molding

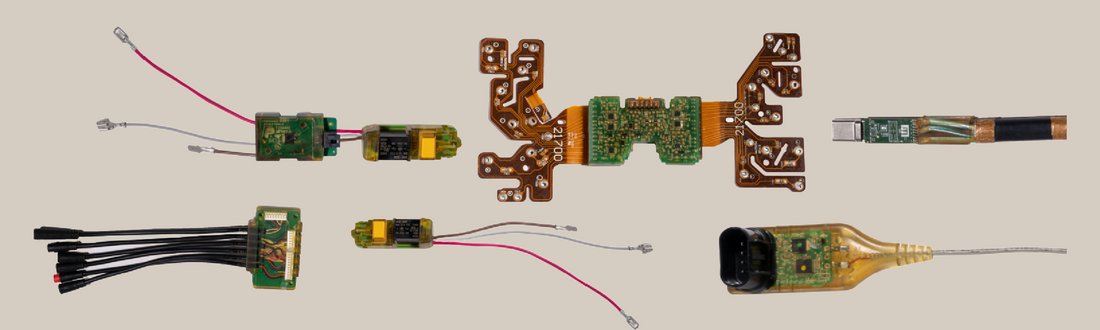

LPM has been widely applied in various cutting-edge fields, such as electronic bikes, automobiles, marine, PCB encapsulation, and sensors.

COMOSS’ professional LPM team will assist you in evaluating how LPM can optimize your products and provide a customized LPM solution. Contact us at sales@comoss.com, now!